Enhancing CNC Occupational Safety Through VR Training: A Comprehensive Approach

Introduction

In today’s advanced manufacturing landscape, Computer Numerical Control (CNC) machines play a critical role in the precision and efficiency of production processes. However, the operation of these machines comes with significant safety risks. Ensuring that operators are adequately trained is a regulatory requirement and a crucial component of maintaining a safe and productive workplace. While effective, traditional training methods often fall short of providing the hands-on experience necessary to prepare workers for real-world scenarios fully. This is where Virtual Reality (VR) training offers a transformative solution.

The Critical Need for CNC Occupational Safety

CNC machines are highly sophisticated tools for cutting, shaping, and finishing materials with exceptional accuracy. However, improper handling, lack of training, or insufficient understanding of safety protocols can lead to severe accidents, injuries, and operational disruptions. According to industry data, machinery-related accidents are among the top causes of workplace injuries, with CNC machines being particularly hazardous due to their complexity and power.

This underscores the importance of comprehensive training programs that go beyond basic instruction and focus on real-world application and safety awareness. Employers are responsible for equipping their workforce with the knowledge and skills needed to operate CNC machines safely and effectively, which can significantly reduce the risk of accidents and improve overall operational efficiency.

What is VR Training?

Virtual Reality (VR) training is an innovative educational tool that uses VR technology to simulate real-world environments. It allows trainees to interact with virtual objects and scenarios, offering a risk-free platform to practice and refine their skills. In the context of CNC operations, VR training provides an immersive experience where users can engage in hands-on learning without the associated dangers of operating actual machinery. This training method is safer and more effective in helping trainees retain information and apply it in real-world situations.

Key Features of CNC Occupational Safety VR Training

Our CNC Occupational Safety VR Training module is designed to meet the specific needs of CNC operators. It incorporates several key features that make it a valuable addition to any safety training program:

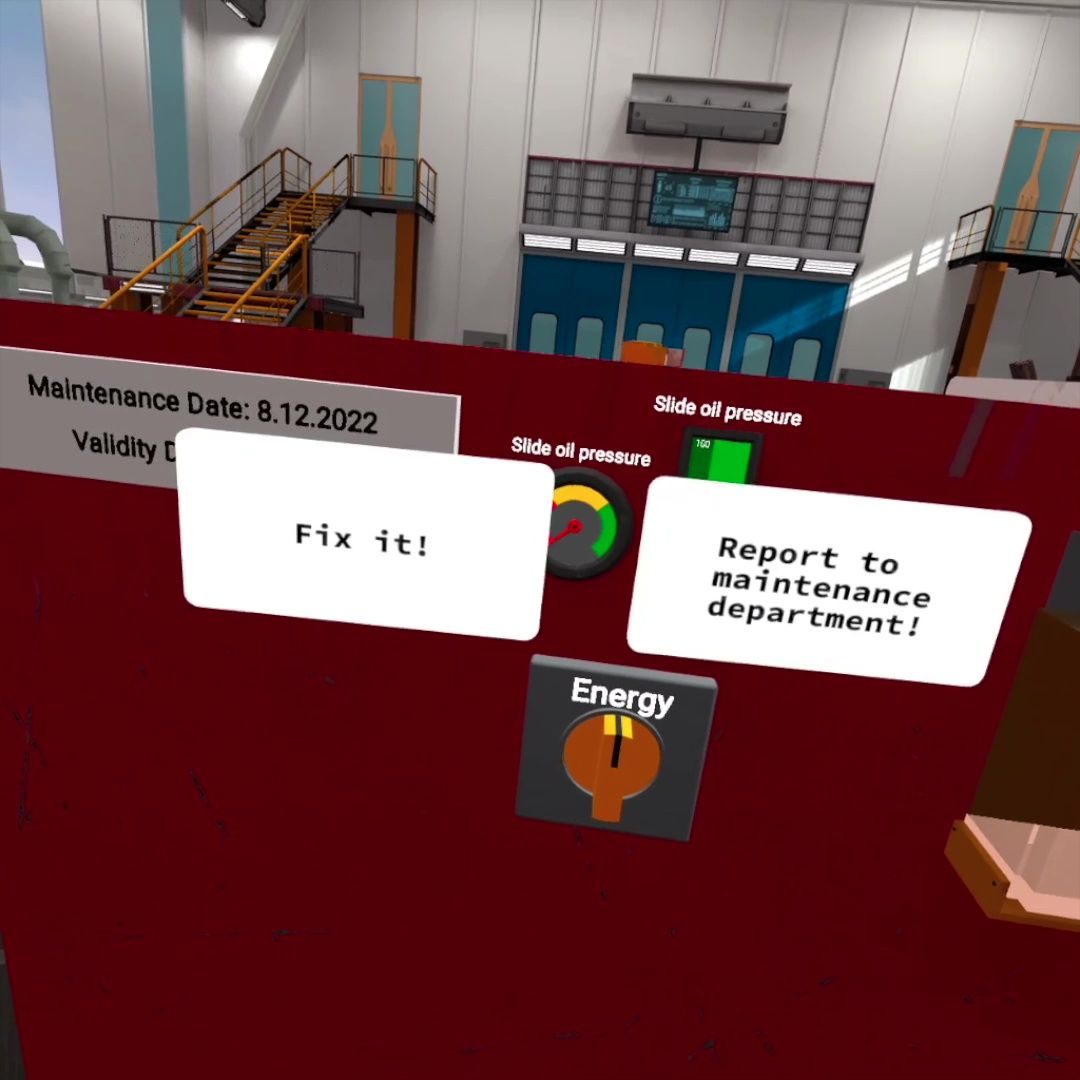

- Realistic Scenarios: The VR module recreates a virtual CNC workshop environment, allowing trainees to perform tasks such as machine setup, operation, maintenance, and troubleshooting. These scenarios are designed to mirror the challenges faced in real-life CNC operations, providing a practical learning experience.

- Comprehensive Guidance: The training module offers step-by-step instructions on essential safety protocols, ensuring that trainees are well-prepared to handle CNC machinery. This includes everything from understanding machine controls and safety mechanisms to implementing emergency procedures.

- Interactive Learning: The VR environment is fully interactive, enabling trainees to engage with the virtual tools and machines just as they would in a physical workshop. This interaction helps reinforce learning by allowing trainees to apply their knowledge in a controlled, immersive setting.

- Immediate Feedback: One significant advantage of VR training is the ability to provide instant feedback. If a trainee makes a mistake, the system can immediately highlight the error and provide corrective guidance, helping to solidify proper techniques and safety practices.

Benefits of CNC Occupational Safety VR Training

- Enhanced Safety Awareness: VR training emphasizes the importance of safety protocols and helps trainees understand the potential risks associated with CNC operations. By practicing in a simulated environment, trainees develop a safety-first mindset that translates to better practices in the workplace.

- Improved Skill Retention and Performance: Research shows that immersive learning experiences like VR training lead to higher retention rates than traditional methods. Trainees are more likely to remember and apply what they've learned when they've had the opportunity to practice in a realistic, hands-on setting.

- Cost-Effective Training Solution: While VR technology requires an upfront investment, the long-term benefits, such as reduced accident rates and improved productivity, make it a cost-effective solution. Additionally, VR training reduces the need for expensive physical resources and minimizes downtime associated with traditional training methods.

- Scalable and Customizable: VR training modules can be easily adapted to meet the specific needs of different operators and scenarios. Trainees can learn at their own pace, revisit challenging modules, and receive personalized training that addresses their unique learning requirements.

Conclusion

Contact us

Approved & Certified by Bureau Veritas

We are proud to be member of