Managing Volatile Organic Compounds (VOCs) Onboard Ships: A Comprehensive Guide for Tanker Crews

Volatile Organic Compounds (VOCs) are a significant environmental and safety concern in the maritime industry, particularly on tankers transporting oil, chemicals, and liquefied gases. These compounds, released from marine fuels, paints, and cargo handling operations, contribute to air pollution, ozone depletion, and health risks for crew members. To ensure safe and compliant operations, maritime professionals must be well-versed in VOC management, regulations like MARPOL Annex VI, and effective control measures.

What Are Volatile Organic Compounds (VOCs)?

VOCs are organic chemicals that quickly vaporize at room temperature, releasing harmful gases into the atmosphere. These compounds can be found in a variety of materials and operations onboard ships, including:

- Marine Fuels: The burning of marine fuels in engines generates VOC emissions, contributing to air pollution.

- Paints and Coatings: VOCs are present in paints and coatings used on ships, particularly during application and drying.

- Cargo Handling: VOCs are emitted during the handling and storage of volatile cargoes, such as crude oil, gasoline, and chemicals.

- Tank Cleaning and Venting: Cleaning and venting cargo tanks release significant VOCs into the atmosphere.

Given their prevalence onboard ships, VOC emissions pose a severe environmental and human health risk. Without proper control measures, VOCs can contribute to air pollution, climate change, and respiratory illnesses among crew members.

The Environmental Impact of VOCs

Air Pollution and Ozone Depletion

VOCs significantly contribute to air pollution, particularly in emission control areas (ECAs), where stricter regulations apply to limit emissions. When VOCs are released into the atmosphere, they react with nitrogen oxides (NOx) to form ground-level ozone, a key component of smog. This reduces air quality and contributes to global warming and ozone layer depletion.

Impact on Marine Ecosystems

VOC emissions also have indirect effects on marine ecosystems. Ground-level ozone, produced as a byproduct of VOCs, can harm vegetation and aquatic life. In addition, the accumulation of VOCs in the atmosphere can lead to acid rain, which damages marine habitats and affects biodiversity.

Health and Safety Risks of VOCs

Exposure to VOCs can pose significant health risks for crew onboard tankers, especially during cargo handling, tank cleaning, and fuel combustion. Short-term exposure to high levels of VOCs can cause symptoms such as headaches, dizziness, and respiratory issues. Long-term exposure has been linked to more severe conditions, including liver and kidney damage, nervous system disorders, and even cancer.

Key Health and Safety Precautions for VOC Management:

- Personal Protective Equipment (PPE): Crew members must wear appropriate PPE, including respirators, gloves, and protective clothing when working with VOC-emitting materials.

- Proper Ventilation: Ensuring proper ventilation in enclosed spaces, such as cargo tanks and engine rooms, is essential to reduce VOC concentrations.

- Emergency Response Procedures: Crews should be trained in emergency response procedures to deal with VOC leaks, spills, or exposure incidents.

- Regular Health Monitoring: Crew members exposed to VOCs should undergo regular health monitoring to detect any early signs of exposure-related illnesses.

Regulatory Framework: MARPOL Annex VI and VOC Control

MARPOL Annex VI, the International Convention for the Prevention of Air Pollution from Ships, sets out stringent regulations for controlling air pollution, including VOC emissions, from ships. Under this annex, ships must implement various measures to limit VOC emissions, particularly in ECAs, where stricter limits apply.

Key Regulations Governing VOC Emissions:

- VOC Management Plan: Ships must develop and implement a VOC management plan that outlines procedures for minimizing VOC emissions during cargo handling, tank cleaning, and other operations.

- Vapor Emission Control Systems (VECS): VECS is mandatory for certain tankers and is designed to capture VOCs released during cargo transfer and tank venting, preventing them from entering the atmosphere.

- Emission Control Areas (ECAs): In designated ECAs, where air pollution is a significant concern, stricter regulations apply to VOC emissions. Ships operating in these areas must adhere to additional control measures to minimize environmental impact.

In addition to MARPOL Annex VI, various industry guidelines and national regulations provide further direction on managing VOC emissions onboard ships. Compliance with these regulations is critical for ensuring the crew's safety and the marine environment's protection.

Best Practices for VOC Management Onboard

Effectively managing VOCs onboard requires a combination of operational controls, technological solutions, and crew training. Below are some best practices for minimizing VOC emissions and ensuring compliance with environmental regulations:

1. Implementing VOC Control Measures

One of the most effective ways to manage VOC emissions is using Vapor Emission Control Systems (VECS). VECS capture VOCs during cargo loading and unloading operations, preventing them from being released into the atmosphere. Additional control measures, such as scrubbers, can further reduce VOC emissions from exhaust gases.

2. Alternative Fuels and Technologies

Using alternative fuels, such as liquefied natural gas (LNG), hydrogen fuel cells, and battery-electric propulsion systems, can significantly reduce VOC emissions. These cleaner fuels produce fewer harmful emissions than traditional marine fuels, making them an attractive option for ships operating in ECAs.

3. Low-VOC Paints and Coatings

Switching to low-VOC paints and coatings can help reduce VOC emissions during maintenance and repair activities. These products contain fewer volatile chemicals, minimizing their impact on air quality.

4. Proper Cargo Handling Procedures

During cargo handling and tank cleaning operations, it is essential to follow proper procedures to minimize VOC emissions. This includes using closed-loop systems for tank venting, maintaining cargo tanks to prevent leaks, and ensuring that cargo residues are properly cleaned.

5. Training and Certification

Comprehensive training for crew members is essential for ensuring that VOC management procedures are implemented effectively. Courses like Volatile Organic Compounds (VOCs) help maritime professionals understand the sources of VOCs, regulatory requirements, and best practices for emission control.

How Our VOC Management Training Can Help

At Maritime Trainer, we offer an in-depth e-learning module on Volatile Organic Compounds (VOCs) that equips maritime professionals with the knowledge and skills they need to manage VOC emissions effectively. Our course covers everything from VOC sources and regulatory compliance to emission control technologies and safety precautions.

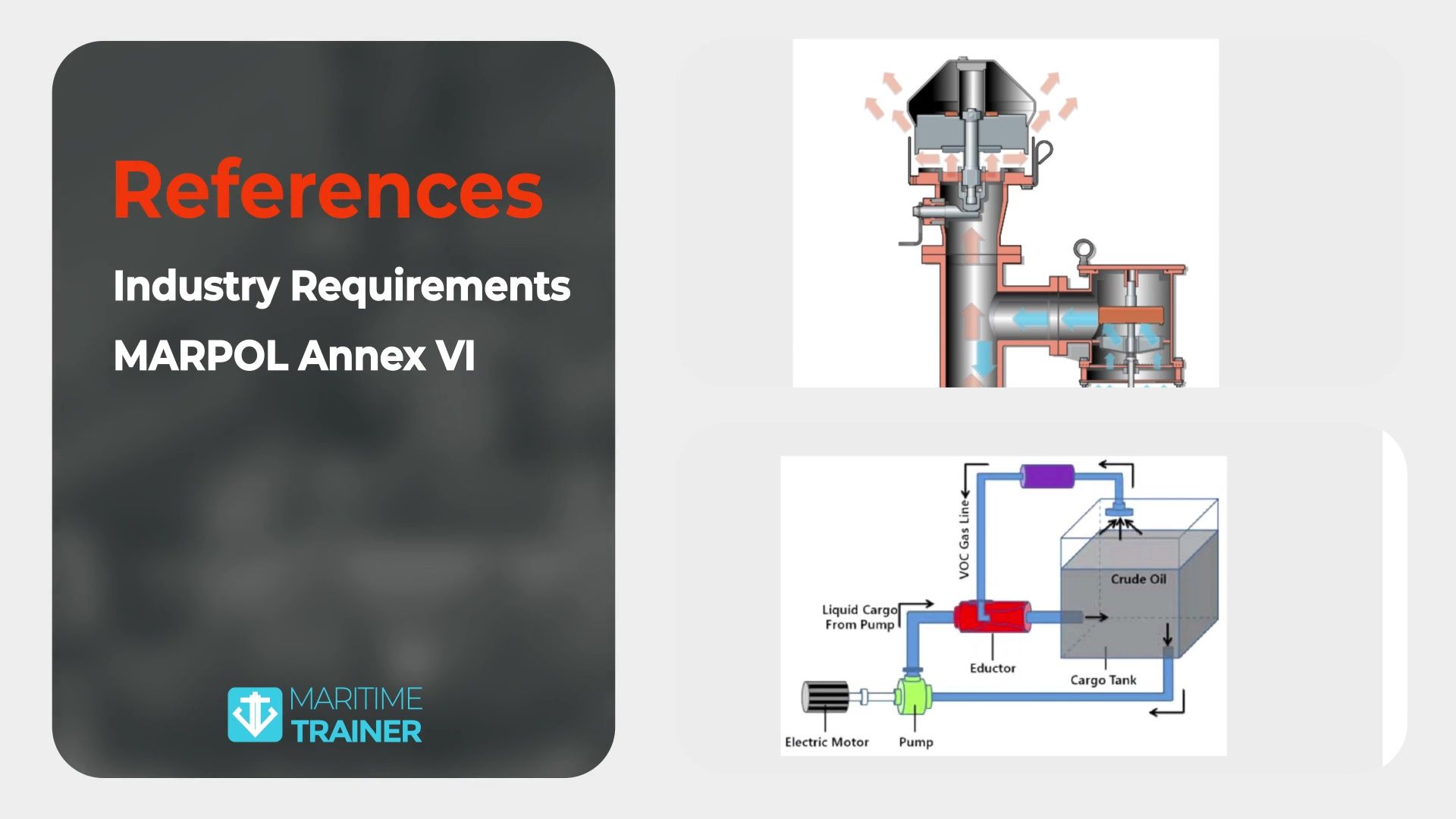

What You’ll Learn:

- The sources and properties of VOCs onboard ships

- MARPOL Annex VI regulations and emission control areas (ECAs)

- The operation of VECS and other VOC control measures

- Health and safety precautions for working with VOCs

- The role of alternative fuels and technologies in reducing VOC emissions

Course Details:

- Duration: 28 minutes

- Language: English

- Skill Level: Operational

- Assessment: No

- Certification: N/A

By completing this course, you will gain the expertise needed to minimize VOC emissions, ensure compliance with MARPOL Annex VI, and protect the health and safety of your crew.

Conclusion

Managing volatile organic compounds (VOCs) onboard ships is critical to maritime operations, particularly for tankers carrying hazardous cargo. The environmental impact of VOC emissions, combined with the health risks to crew members, makes it essential for maritime professionals to implement effective VOC control measures and comply with international regulations like MARPOL Annex VI.

Contact us

Approved & Certified by Bureau Veritas

We are proud to be member of