Mastering Iron Works Safety with VR: Revolutionizing Occupational Safety Training

In the dynamic and potentially hazardous environment of ironworks, ensuring workplace safety is paramount. Traditional safety training methods, while effective, often need to catch up when it comes to providing hands-on, practical experience in a risk-free environment. This is where Virtual Reality (VR) training steps in, offering an immersive and interactive solution that enhances safety and boosts operational efficiency. In this blog post, we'll figure out how Iron Works Occupational Safety VR Training is reshaping the landscape of industrial safety training and why it’s a game-changer for ironworkers.

The Evolution of Safety Training: Why VR?

For decades, occupational safety training has relied on theoretical lessons, static videos, and sporadic on-the-job guidance. While these methods provide foundational knowledge, they can’t replicate the real-life challenges workers face daily. Mistakes during actual training can be costly regarding financial loss and human injury. VR changes that equation.

Key Features of the Iron Works VR Training Module

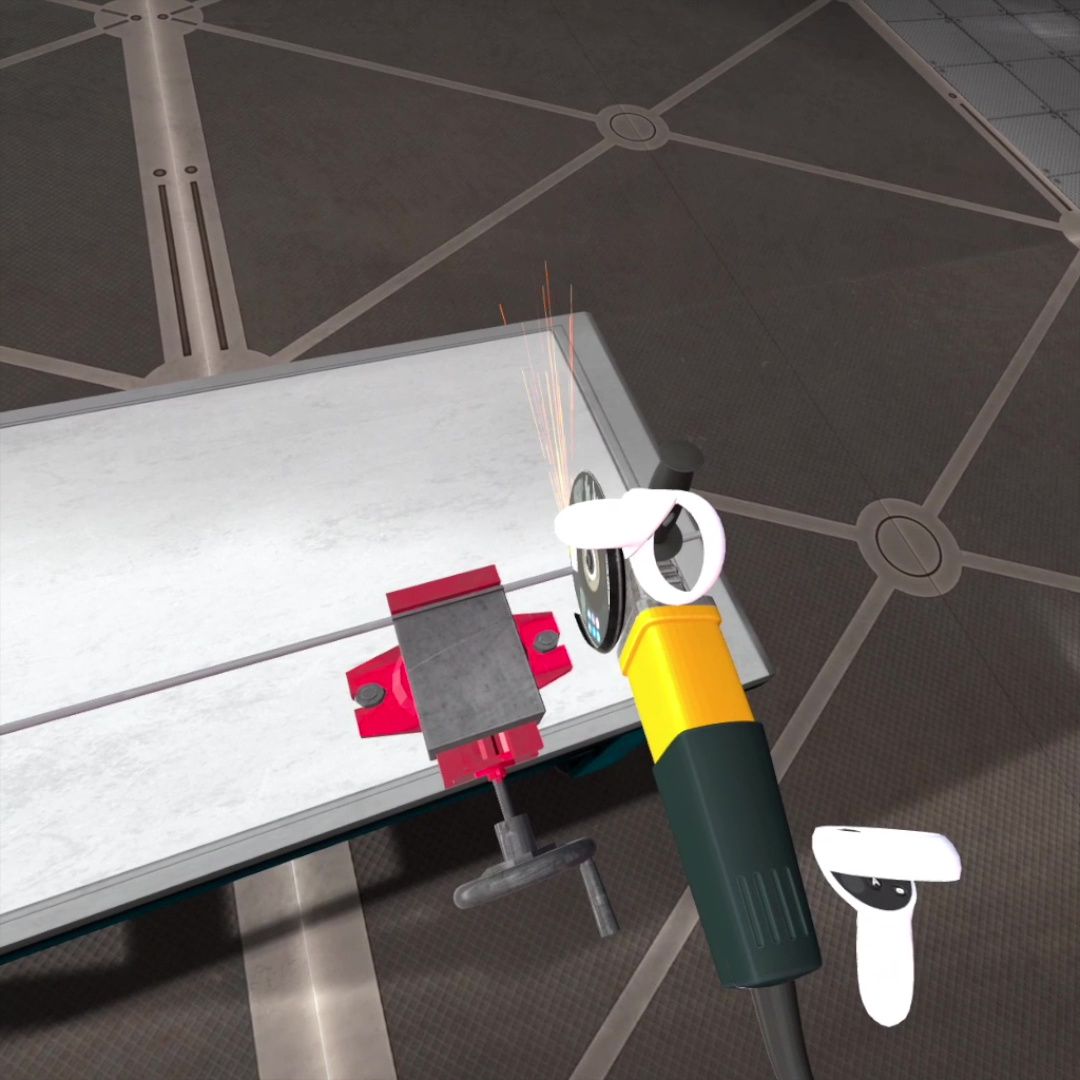

1. Immersive, Realistic Scenarios

Our VR module brings ironworkers into a fully realized virtual environment. From handling heavy machinery to working with industrial materials, trainees will experience the same situations they would on the shop floor. This provides a realistic sense of what to expect in the workplace and prepares them for the unexpected.

2. Comprehensive Safety Protocols

The VR training module covers every aspect of ironworks safety, including machinery setup, operation, and maintenance. Trainees are guided through each step with clear instructions and real-time feedback, ensuring they understand critical safety protocols thoroughly.

- Proper use of heavy equipment like cutting tools and grinders.

- Safe handling of flammable materials and hazardous chemicals.

- Correct procedures for equipment setup, operation, and shutdown.

- Emergency response protocols for fire hazards and other workplace accidents.

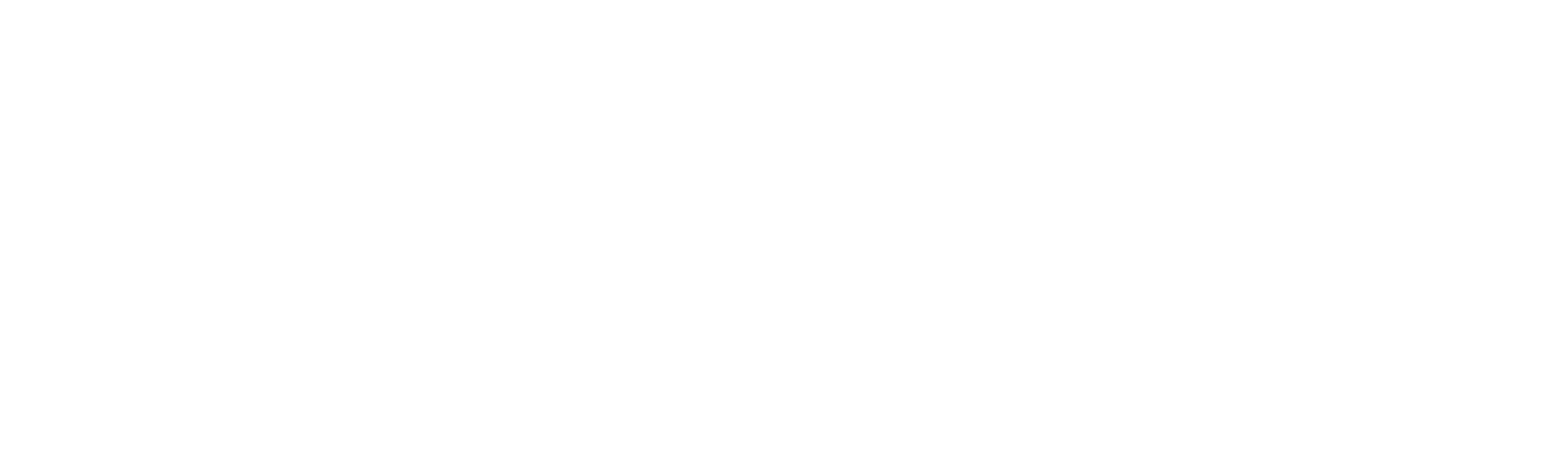

3. Interactive Learning for Better Retention

Unlike passive learning methods, VR engages users in a fully interactive training experience. Trainees aren't just watching or listening—they're actively participating. This hands-on approach has been proven to enhance information retention and improve overall skill development. Workers gain a deeper understanding of safety procedures, making them more likely to remember and apply what they've learned on the job.

The Benefits of VR Training for Ironworkers

1. Reducing Risk, Improving Safety

Safety is the number one priority in any ironworks setting. By allowing workers to make mistakes and learn from them in a virtual environment, VR significantly reduces the risk of real-world accidents. Workers can practice operating machinery, responding to emergencies, and following proper protocols without the pressure of real-world consequences. This leads to greater confidence and competence when stepping onto the shop floor.

2. Customizable and Scalable Training

VR training modules can be tailored to meet the specific needs of your operation. Whether you need to focus on machinery safety, chemical handling, or emergency procedures, the training can be customized to suit your requirements. Additionally, VR training can be scaled across multiple teams or locations, making it an efficient solution for larger organizations.

3. Flexible Learning Anytime, Anywhere

Normal Traditional training programs often require workers to attend in-person sessions, which can be difficult to schedule around busy workdays. VR offers a flexible alternative. Trainees can complete their safety training at their own pace, whether they're at home, in the office, or on-site. This flexibility ensures everyone gets the training they need without disrupting day-to-day operations.

4. Enhanced Engagement and Motivation

Workers are more likely to engage with training that is immersive and interactive. VR adds an element of gamification to the learning process, making it more enjoyable and engaging. As a result, workers are more motivated to complete their training, and organizations see higher participation rates.

Why Choose Iron Works Occupational Safety VR Training?

In an industry as demanding as ironworks, staying updated with the latest safety practices isn't just a recommendation—it's a necessity. Our Iron Works Occupational Safety VR Training provides the cutting-edge tools to ensure your team is prepared, protected, and productive.

- Cost-Effective Training: VR saves time and money by reducing the need for physical training resources and minimizing the risk of accidents.

- Proven Results: Studies show that VR-based learning enhances knowledge retention by up to 80% compared to traditional methods. Trainees complete courses more quickly and feel more confident in their abilities.

- Measurable Progress: Our training platform allows you to track individual progress, ensuring that all workers meet your organization’s safety standards.

Conclusion: Take the Next Step Toward a Safer Workplace

Ironworks is a physically demanding and potentially hazardous profession, but with the proper training, workers can be prepared to face those challenges head-on. Our Iron Works Occupational Safety VR Training offers a groundbreaking approach to safety training, equipping workers with the skills and confidence they need to excel in their roles while staying safe.

Contact us

Approved & Certified by Bureau Veritas

We are proud to be member of